A Legacy of Precision

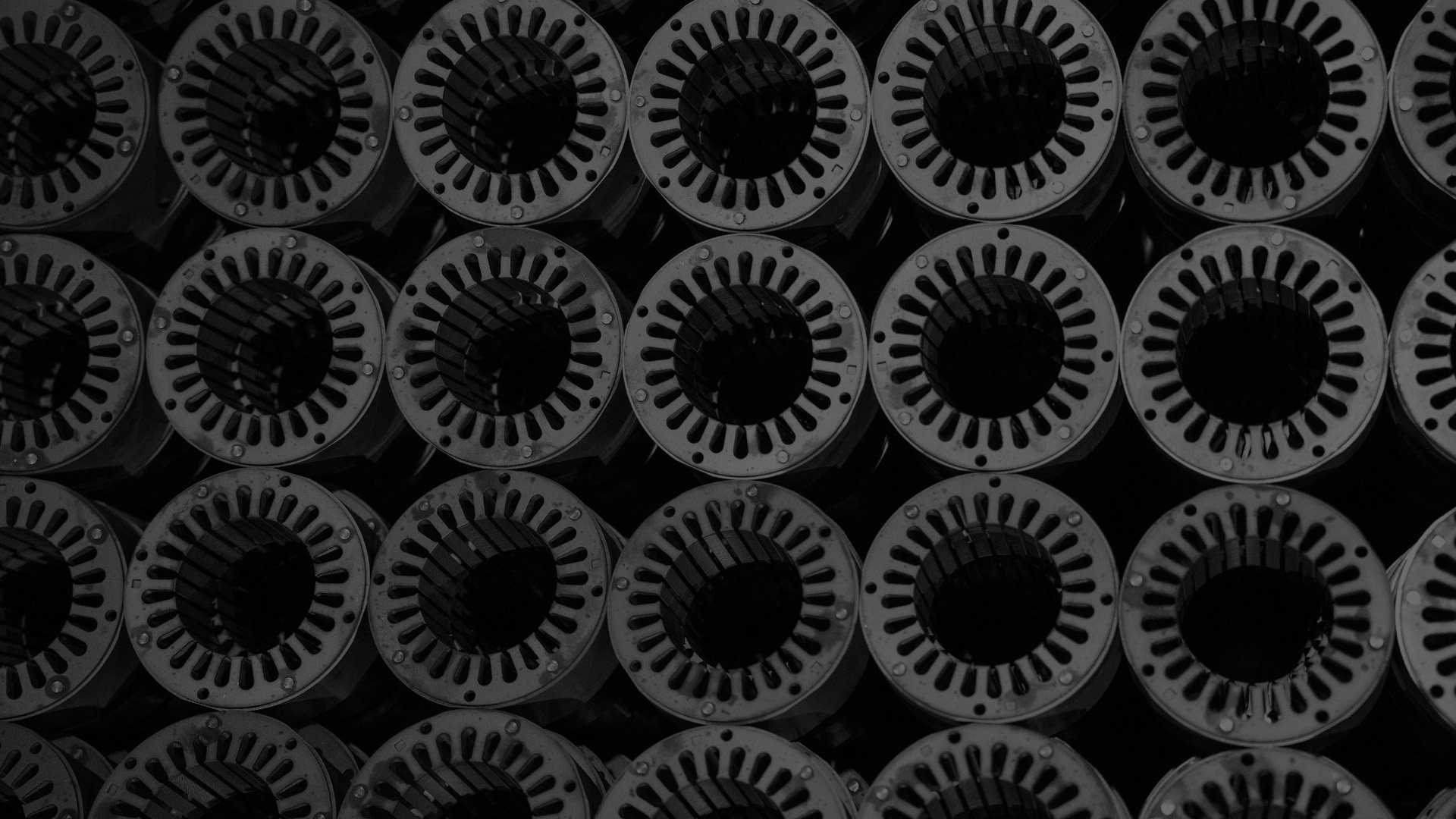

Kapri Core Solution Pvt. Ltd. is a respected name in the industry, originally established in 1991 by Mr. Deepak Chander Kapri under the name Electro Stamping Tools & Die. In 2010, the company was rebranded as Kapri Core Solution Pvt. Ltd., marking a new phase of growth and diversification. We began with the manufacturing, repair, and maintenance of tools, and over the years, expanded our capabilities to include high-volume stamping production, supported by an in-house Rotor Die Casting Unit, a fully equipped tool room with all the imported tools and a dedicated Hi-Perm Unit for specialized, high-performance components.

At Kapri Core Solution Pvt. Ltd., we specialize in delivering high-precision stamping solutions tailored to meet the evolving needs of modern industries. With over three decades of experience, we have established ourselves as one of India’s leading stamping manufacturers—known for our commitment to quality, innovation, and customer satisfaction.

Our integrated manufacturing setup allows us to maintain complete control over quality, lead times, and customization.

Our Values

At KCSPL, our values are the backbone of our operations. They guide how we manufacture, collaborate, and grow. With a strong focus on quality, reliability, and customer satisfaction, we strive to deliver precision stamping solutions while upholding the highest standards of safety, integrity, and innovation.

Our Mission

As one of India’s leading stamping manufacturers, our mission is to deliver high-quality, precision-engineered components tailored to our customers’ unique needs. We are committed to a deeply customer-centric approach, fostering long-term partnerships through continuous innovation, operational excellence, and sustainable manufacturing.

Our Vision

To be a globally recognized leader in precision stamping solutions - trusted for our innovation, quality, and customer-first approach.

We aim to expand our global footprint by continuously advancing our technology, strengthening partnerships, and driving sustainable manufacturing excellence across international markets.

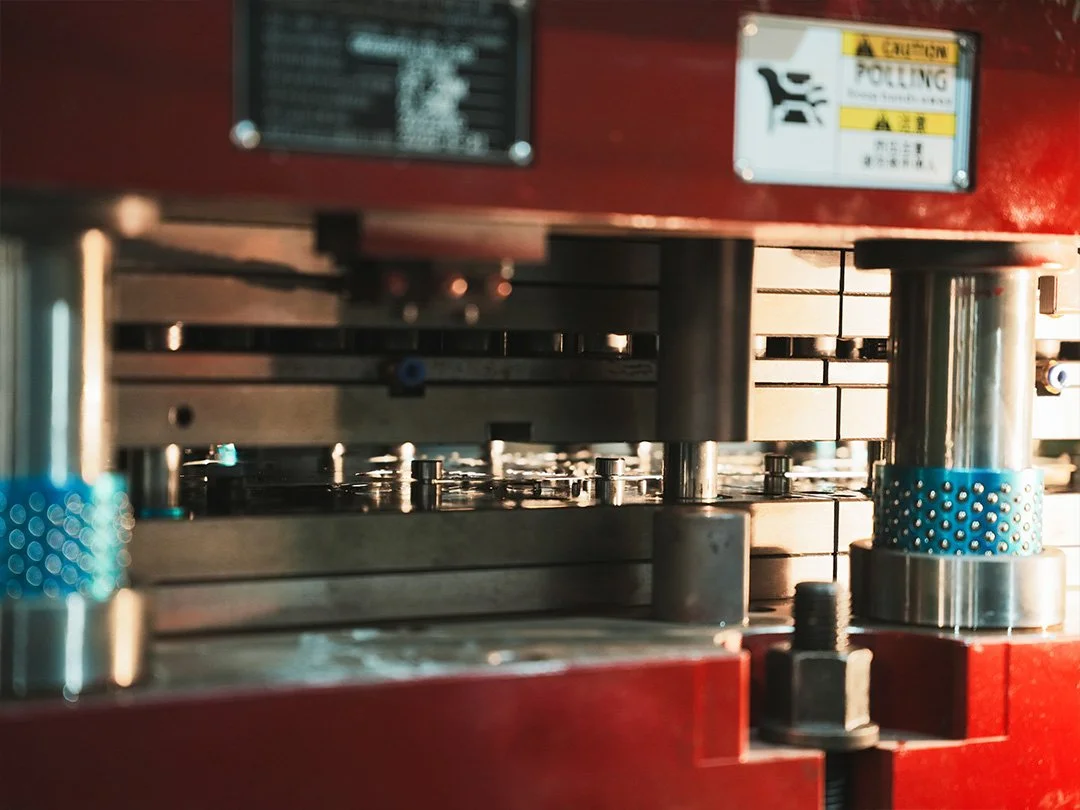

Manufacturing Capabilities at A Glance

Plant Specifications

Our state-of-the-art stamping manufacturing facility is designed to meet the demanding requirements of our customers. With modern infrastructure, advanced press shop capabilities, and a strong focus on quality and safety, we ensure consistent, high-volume, and precision-driven production.

| Parameter | Details |

|---|---|

| Total Land Area | 40,000 sq ft |

| Built-up Area |

Stamping : 17000 sq ft Hi Perm : 11000 sq ft Casting : 6000 sq ft Tool Room : 5500 sq ft |

| Shift Operations | 24*7 |

| Total Manpower | 200+ |

| Press Type | Hi-Speed Power Presses |

| Press Capacity Range | 30 Tons – 300 Tons |

| Year of Establishment | 1991 |

Production Capacity

Robust production infrastructure delivering high-volume output with precision and consistency, backed by clearly defined capacity metrics.

| Processes | Monthly Production |

|---|---|

| Steel Punching | Over 2000 MT of Steel Punching |

| Hi-Perm | Over 1000 MT of Stator Annealing |

| Rotor Casting | Over 5 Lakh Rotors |

| End Shield | Over 1 lakh Aluminium End Shield |

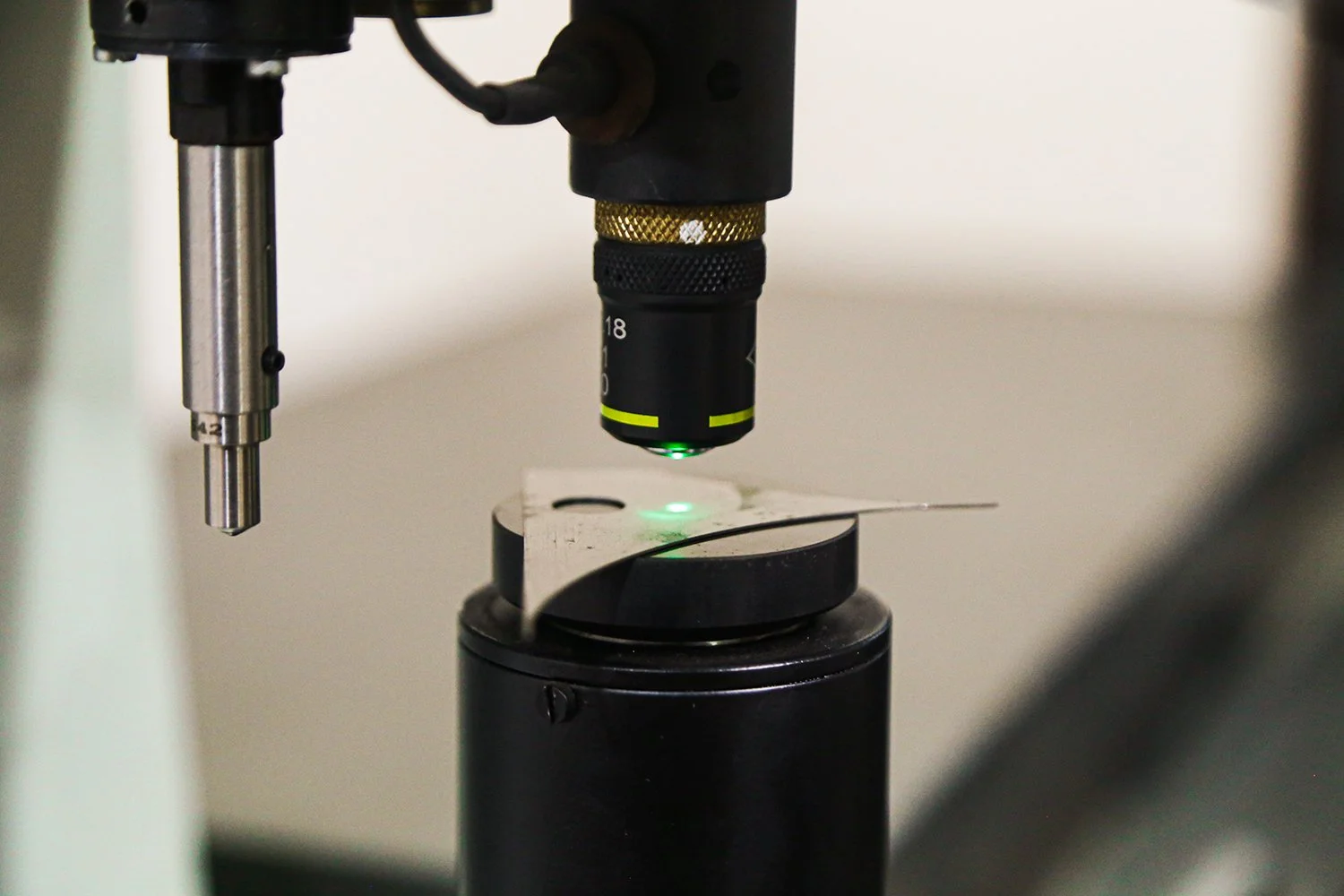

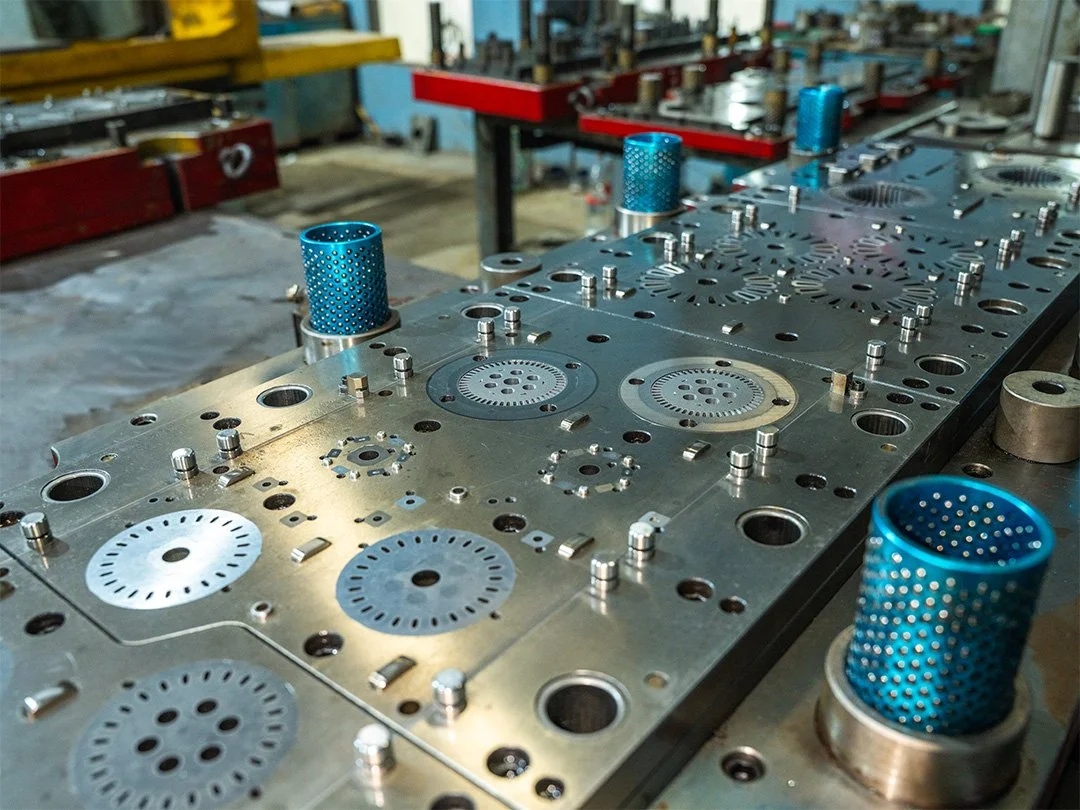

Tool Room Facilities

Our imported tools & in-house tool room support die design, development, and maintenance, ensuring shorter lead times and consistent quality.

| Facility | Availability |

|---|---|

| In-house Die Design | Yes |

| CNC Machining | Yes |

| Wire Cut EDM | Yes |

| Surface Grinding | Yes |

| Jig Boring | Yes |

From Punching to Casting — Complete In-House Facility